Kester KSTK100-1.5 Tin Roll K100LD Lead Free 1,5mm 1Kg

Product Code: 570KSTK100-1.5-1KG

Wire 275-K100LD Lead Free Sn 99.3 Cu0.7 + Ni

The Kester 275 / K100LD alloy wire is made of tin copper eutectic alloy with nickel in a controlled quantity.

Combined with flux 275 it is classified as ROL0 No Clean

Exceeds J-STD-004 requirements and meets Bellcore GR-78 specifications

Features:

- RoHS compliant

- Excellent ascent and wettability

- Brilliant and uniform welds

- Facilitates retouching operations

- It doesn't smell

- Virtually no residues

- Not organic

- Halogen free

- Large process window.

- Low cost, lead free alloy

K100LD Benefits and Performance:

The K100LD alloy is a Lead Free alloy wire (lead free as per RoHS regulation) designed for manual soldering and for Rework applications. K100LD is a new Kester patent developed for manual sandblasting; the alloy is composed of nickel-tin-copper and other elements designed to reduce the migration of the protective metals of the tips or wells during welding and to give better wetting performance.

The K100LD wire is supplied with a No-Clean flux which allows it to be used in any Lead Free application with ease and reliability.

UltraPure K100LD performance:

Compatibility with Lead Free Metallization: K100LD has excellent performance with all types of components and PCB metallizations. This reduces the problems of non-wettability by offering good dissusion and migration of the alloy.

Appearance of solder joints: K100LD offers exceptional lintness and smoothness of the weld meniscus with a very low shrinkage effect similar to Tin-Lead alloys. The luster of this alloy makes the visual inspection of the weld menisci the same as traditional alloys; this reduces the time required to reform the operators assigned to this control.

Low Copper Dissolution: K100LD minimizes the Copper dissolution of components and PCBs in the alloy. this reduction helps to preserve the metallization of the parts being welded.

Wettability: the K100LD alloy is designed to have excellent wettability of the Lead Free components but like all other Lead Free alloys the wetting speed can be slightly reduced compared to the classic SnPb. Selecting the correct flux type for the required welding technique ensures good results.

A low cost Lead Free alloy: K100LD is a Tin-Copper based alloy without the addition of Silver. If you compare it to the SAC305 alloy, the lack of Silver makes it much cheaper.

Low Lead Contamination: K100LD is manufactured with a lead content of less than 0.05% to help ensure RoHS compliance.

Flux Compatibility: The K100LD wire alloy contains the optimum amount of Flux for a good solder. The wettability of Lead Free alloys is lower than SnPb alloys and the Flux content is one of the critical parameters to guarantee a good Lead Free soldering. Additionally, Kester Fluxes do not burn easily as they are designed for the higher soldering temperatures used with Lead Free alloys.

Lead Free Alloys and Tips

Due to the slower wetting behavior of Lead Free alloys it is essential to use suitable welding equipment and techniques to ensure fast and reliable welding.

The following tips will help you achieve the desired results when manually soldering with Lead Free Kester K100LD alloy :

- Use the correct geometry of the soldering tips (tips as large as possible compared to the solder pad)

- Use a soldering temperature between 360 ° C - 400 ° C

- Slightly increase the Tag Times (contact time) for each welding operation

- Always choose the right percentage of Flux in the welding wire (3% recommended in the K100LD alloy)

- Use the right alloy wire diameter depending on the application

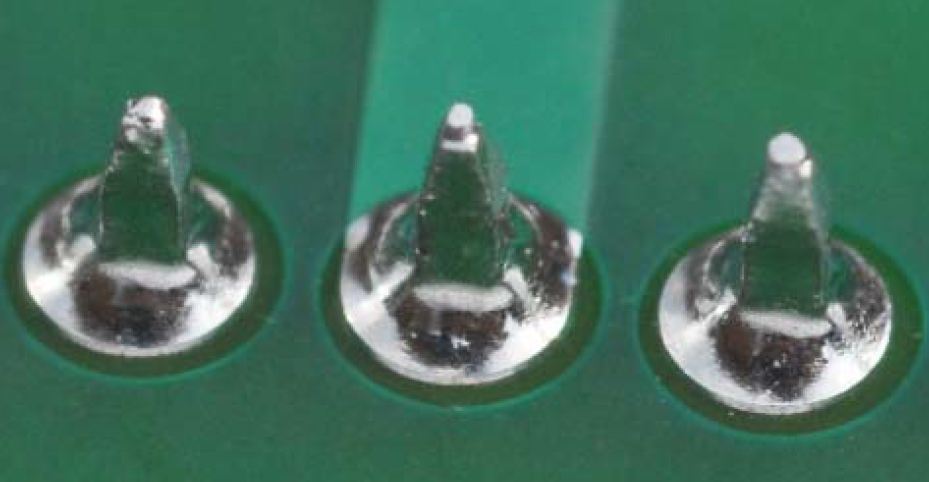

Brilliance of the weld menisci in the Bottom Side with KD100LD

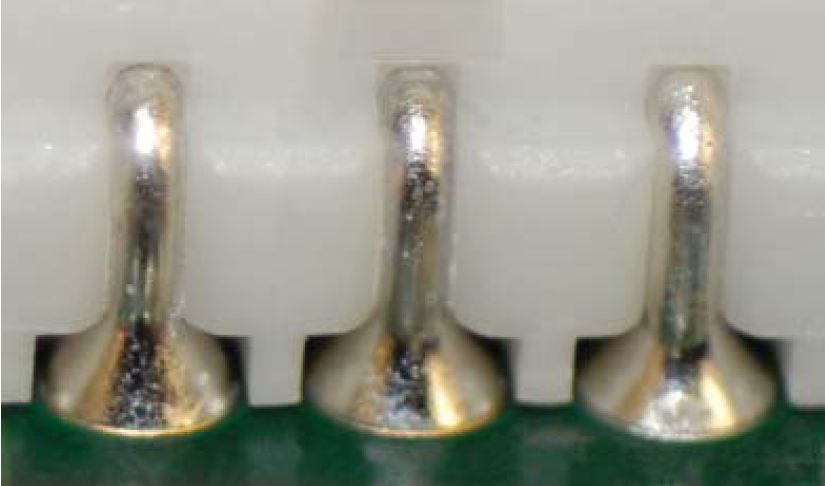

Top side hole filling with KD100LD

Brightness of weld menisci and lack of porosity with KD100LD alloy

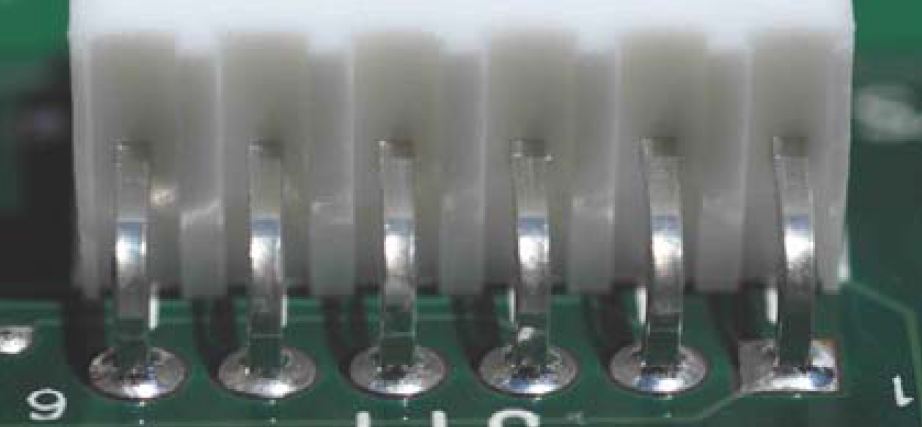

Good wettability and good appearance of the menisci with KD100LD

Bar_K10..919.pdf

(76.46 KB)

Bar_K10..919.pdf

(76.46 KB)