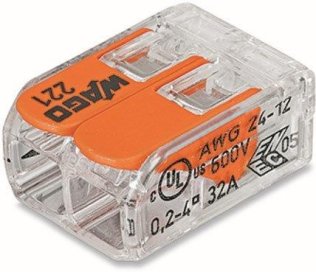

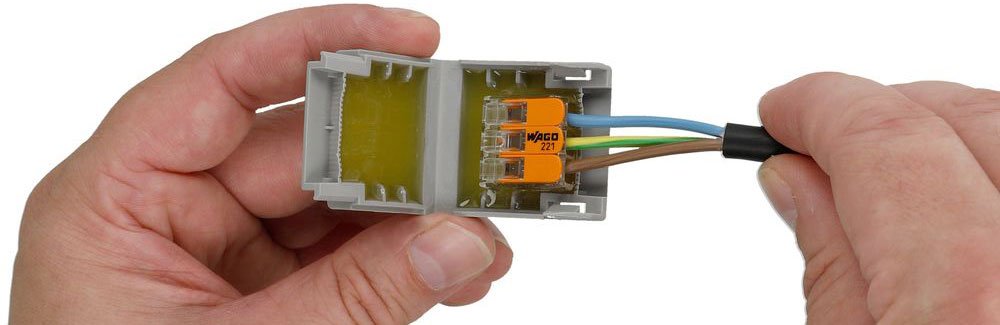

WAGO Gelbox 207-1333 Size 1 (33 x 17 x 52 mm)

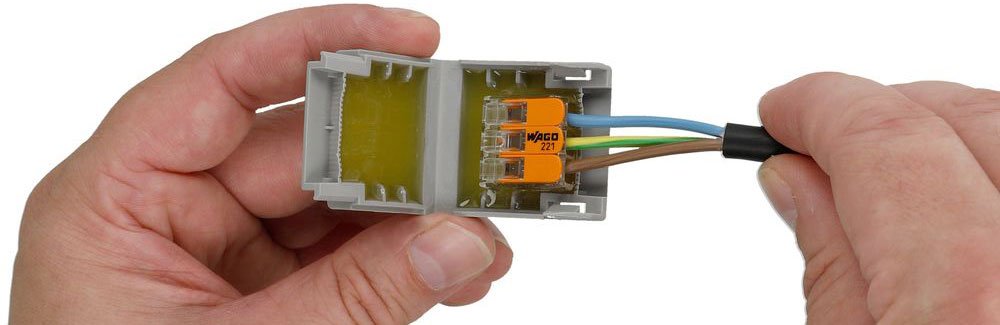

Condensation, heavy rains, powerful jets of water: when water meets electricity, short circuits are the order of the day. A proven solution can be encapsulation. But now you can get reliable moisture protection for the junction clamps even faster and easier thanks to the WAGO GelBox. It is immediately ready for use in a wide range of applications, for low and very low voltages.

Benefits

- Easy, quick and safe application

- Ready for use, convenient and re-enterable later

- Free of silicone

- Label-free

- Suitable for very long-term storage

- The whole system, which includes GelBox and WAGO terminals, has been VDE approved and IPX8 certified.

Dimensions and overall dimensions

- Width 33.6 mm

- Height 17.8 mm

- Depth 52.7 mm

- Weight 26 g

Mechanical Data- Mounting type: for 4mm² WAGO 221 connectors

- Degree of protection IPx8 (2m / 2h) for 60529

- Color: Grey

- Housing material: Polypropylene

What is the WAGO GelBox?

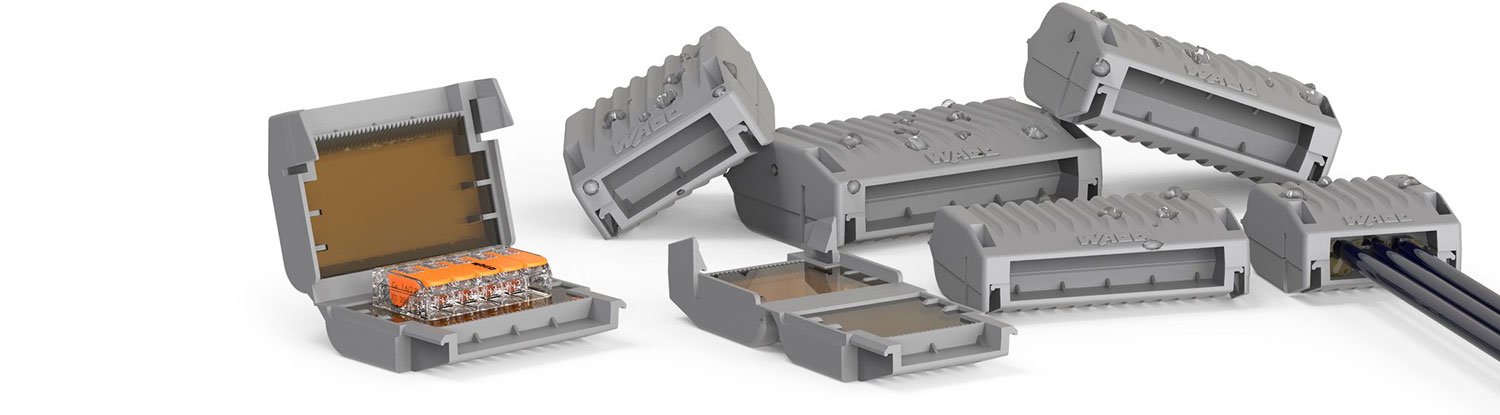

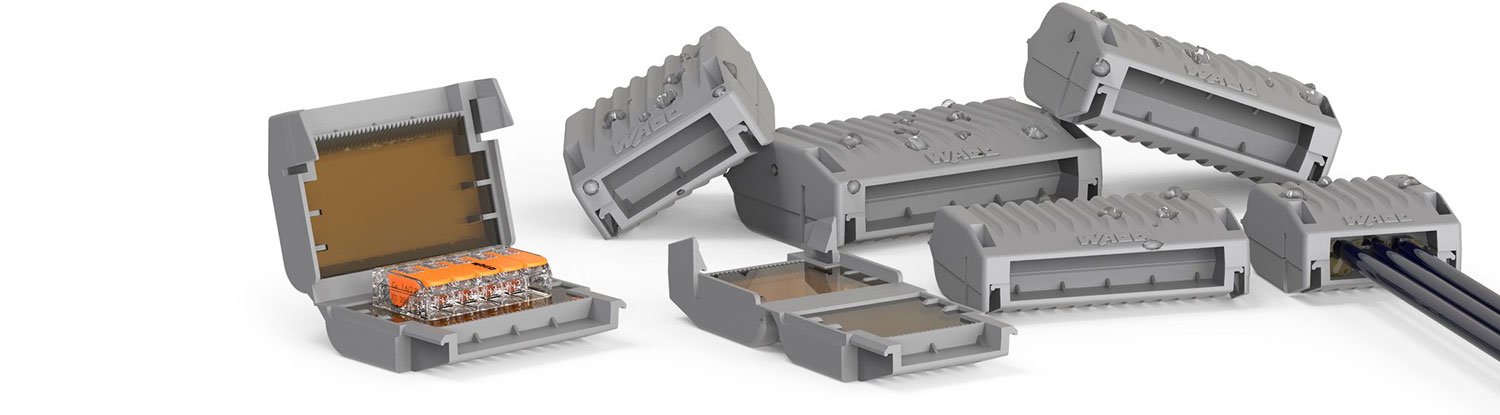

GelBox from WAGO is a compact box pre-filled with silicone-free gel. GelBox is available in six sizes and protects against moisture, offers an IPX8 degree of protection, and is compatible with WAGO's 221 COMPACT series splice terminals and 2273 COMPACT PUSH WIRE® series terminal blocks. With this type of protection the clamps are completely sealed and protected from water, and can remain immersed in liquids even for a long time. Classic filler compounds based on polyurethane and silicone also meet the IPX8 requirements.

However, it is an exclusive property of WAGO's GelBox that protects electrical installations precisely where problems arise: at the connection point, without encapsulating the junction boxes forever. Unlike silicone-based gel, the silicone-free gel from WAGO GelBox allows use in a practically unlimited number of applications.

Where can the GelBox be used?

The WAGO GelBox can be used in a wide range of applications for low and very low voltages. However, the method of use may differ to some extent for the individual voltage ranges. For example: in low voltage applications (eg 230 V) the GelBoxes are used in the junction boxes together with the junction terminals. This is the only way to ensure double insulation to protect cables from electric shocks, as only the conductors are encapsulated in WAGO's GelBox. In SELV (Safety Extra Low Voltage) applications, WAGO terminals can be used with GelBoxes without any additional junction box.

Examples of use

- Bathroom installations (DIN VDE 0100-0705)

- Washing / irrigation systems

- Farms and parks (DIN VDE 0100-0705)

- Areas with swimming pools (DIN VDE 0100-702)

- Parking lighting

- Charging stations and lighting systems in ports

Cellpack quality gel: free of silicone and labels

WAGO relies on the proven quality of Cellpack gel. This famous manufacturer of filling compounds developed the GelBox in collaboration with WAGO. Using Cellpack gel offers three main advantages over traditional encapsulation. First: the gel is silicone free. This allows the GelBox to be used in numerous industrial sectors: even those where paints, solvents and other sensitive products are used, such as in the automotive industry. Second: the silicone-free gel has already reacted, so it does not need to be labeled and can be stored forever. The same cannot be said of all components used to make filler compounds. Also, only the silicone-free gel filling compound allows the user to be able to access the connection again, the key word is: re-accessibility.

Is the WAGO GelBox safe?

To ensure complete protection, the developers of WAGO's GelBox have focused on the system as a whole, consisting of box, clamps and gel. The WAGO GelBox meets the same stringent requirements as the tests for WAGO connectors according to EN 60998. The very high degree of product safety is confirmed and certified by a neutral body in the VDE test report.

Risk of short circuit: what causes the formation of damp?

How is it possible that moisture and water get into the junction box? Condensation can develop, for example, due to a rapid temperature excursion. This is a frequent case during seasonal changes, such as between summer and fall, when the hot air inside the box meets the cold wall of the connector chamber housing and cools down suddenly. As a result, condensation is produced on the inner wall of the housing. This physical effect is further amplified by the loss of power which increases the heat relative to the outside temperature.

The differences in temperatures are then followed by the differences in pressure, which allow fresh air to flow into the connector by introducing the humid. Summing up, a considerable volume of water can accumulate inside the connector.

But the build-up of moisture in the junction boxes can also be caused by heavy rain or a strong jet of water too close to a distribution box. "Moisture within the terminal can redraw the current path leading quickly to a short circuit." However, this is often only felt when the protective devices engage, i.e. when the fuses blow.

Product codes: 207-1333

EAN number: 4055143997805

WAGO Ge.. ds.pdf

(1.05 MB)

WAGO Ge.. ds.pdf

(1.05 MB)